Get True (verb)

/ɡɛt troo/

To ensure that a structure, surface, or element is perfectly level, plumb, and square, aligning with precision and accuracy. Example: "We need to get this frame true before securing it in place."

Specializing in

Plumbing Systems

For Mobile Homes

From Cabins and Cottages, 70-90's Mobile home, to newer Modular homes, we have the knowledge and experience to get your crawlspace sitting true.

Understanding the Plumbing System in Modular Homes

Introduction

The plumbing system in a mobile home is essential for maintaining a comfortable and functional living space. Unlike traditional stick-built homes, mobile homes have a unique plumbing setup that requires careful installation and maintenance to prevent common issues like freezing, leaks, and drainage problems.

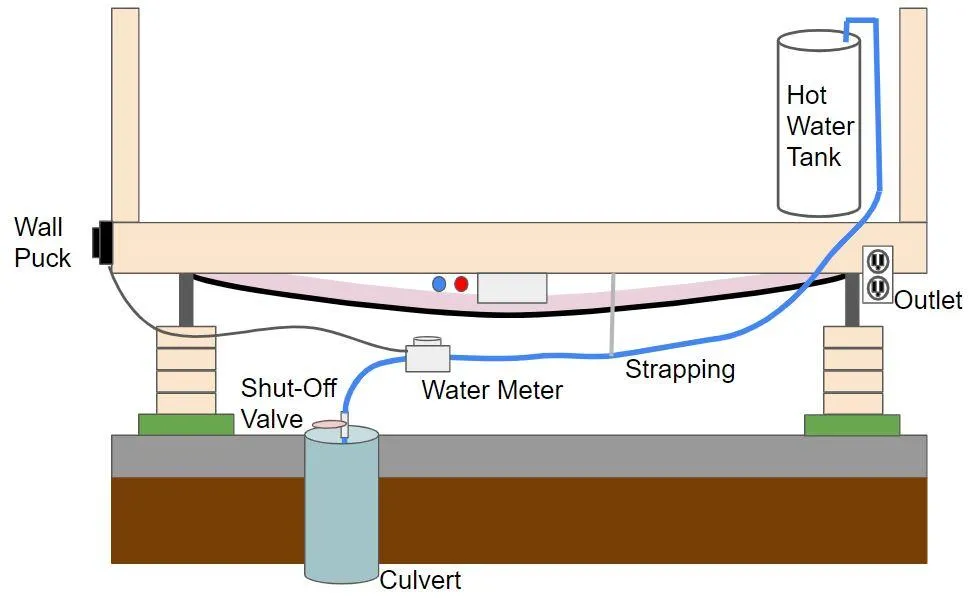

In a mobile home, water enters through a main water line that typically rises from the ground via a culvert and is protected with heat tape to prevent freezing. From there, it travels through the crawlspace to the hot water tank room, where it splits into hot and cold water lines that run under the floor joists within the warm air gap to reach all fixtures in the home.

The sewer system is equally important, with drain lines running under the home, secured to the floor joists, and sloped precisely to ensure proper drainage. These lines join together and exit the belly of the home before connecting to a septic or municipal sewer system. However, if the home is unlevel or improperly maintained, issues like blockages, frozen pipes, and leaks can arise.

Without proper freeze protection, regular maintenance, and correct installation, mobile home plumbing can be prone to costly failures. This guide will break down the essential components of the plumbing system, highlight common problems, and provide expert tips on keeping your plumbing in peak condition year-round.

How it Works

Components of a Modular Home Plumbing System

The plumbing system in a mobile home consists of two main parts: the water supply system and the sewer drainage system. These components work together to provide clean water to the home and remove wastewater efficiently.

Main Water Line – Brings fresh water into the home from an underground source, typically through a culvert, and distributes it to the fixtures.

Hot Water Tank – Heats water before it is sent through the hot water lines to sinks, showers, and appliances.

Cold & Hot Water Lines – Copper, PEX or Poly-B pipes that run beneath the floor joists in the warm air gap to supply water throughout the home.

Sewer Drain Lines – Collect wastewater from sinks, toilets, and appliances, then transport it through a network of pipes before exiting into a septic tank or municipal sewer system

Each of these components requires regular inspection and maintenance to prevent leaks, freezing, and inefficiencies.

Now, let's dive into one of the most critical parts of the system—the main water line.

Water Supply

Main Water Line

The main water line is responsible for delivering fresh water into the home. This pipe typically comes out of the ground out a culvert and is equipped with a shut-off valve to allow homeowners to control the water supply. From there, a 3/4” waterline runs through the crawlspace to the hot water tank room, where the water splits into two separate lines:

• One line goes through the hot water tank to supply heated water.

• The other line remains cold and distributes unheated water to fixtures.

Freeze Protection for the Main Water Line

Since the main water line is exposed to cold temperatures, it must be protected against freezing—typically using heat tape. If a water line freezes, it can expand and burst, leading to costly water damage.

Common Heat Tape Issues

Improper heat tape installation is a frequent cause of pipe failures and even fire hazards.

Some common mistakes include:

Using cheap or low-quality heat tape that fails in extreme temperatures.

Not covering the entire waterline, leaving exposed sections vulnerable to freezing.

Incorrect installation against manufacturer guidelines, such as:

Over-insulating, preventing heat from dispersing properly.

Using heat tape on the wrong type of pipe material.

Spiraling heat tape over itself, which can cause overheating and fire risks.

To ensure proper freeze protection, high-quality heat tape should be installed according to manufacturer instructions, covering the entire pipe and using the correct insulation materials to retain heat.

How it Works

Sewer and Drainage System

The sewer and drainage system in a mobile home is designed to efficiently remove wastewater from sinks, toilets, tubs, and appliances. Unlike traditional homes with underground plumbing, mobile home drain lines run within the warm air gap under the floor joists before exiting the belly of the home and connecting to a septic system or municipal sewer.

Each water fixture (toilets, sinks, showers, and appliances) has a drain line that runs beneath the home, secured to the bottom of the floor joists.

The drain lines are carefully sloped at a precise grade to ensure wastewater flows properly toward the main sewer connection.

These individual drain lines join together and “drop” out of the belly of the home, typically via a 3” ABS pipe in the crawlspace.

Once in the crawlspace, the main sewer line may connect with other drops before running into the ground connection leading to the home’s septic or sewer system.

Common Sewer Line Issues

While a properly installed sewer system works efficiently, poor installation, shifting of the home, or extreme cold temperatures can create plumbing problems.

Some of the most common issues include:

House is Out of Level, Affecting Drainage

• Mobile homes need to be level to maintain proper pipe slope.

• If the home shifts or settles unevenly, the pipes can lose their intended drainage grade, causing slow drainage, backups, or standing water in the pipes.

Improperly Supported Sewer Lines

• Drain pipes should be securely fastened to the floor joists with hangers or supports.

• If not properly supported, pipes can sag, creating low points (bellies) where wastewater collects instead of draining.

• Over time, these bellies cause blockages or freezing issues in winter.

Extended Sewer Lines Freezing in the Crawlspace

• Sewer lines running long distances in a cold crawlspace can cause wastewater to cool down too quickly.

• Over time, slow-moving wastewater can freeze, forming an ice dam that completely blocks the drain.

• This often occurs in extreme cold weather when there is low water usage, allowing standing water in pipes to freeze overnight.

Using the Wrong Type of Heat Tape on Sewer Lines

• While heat tape is commonly used for waterlines, it should be installed carefully on drain pipes.

• Using the wrong type of heat tape or wrapping it improperly can cause the plastic sewer pipe to melt or even catch fire.

• Only manufacturer-approved heat tapes rated for sewer lines should be used, and proper installation guidelines should be followed.

Preventative Measures for Sewer Line Maintenance

Keep your home level to maintain proper drainage slope.

Regularly inspect drain pipes in the crawlspace to ensure they are securely supported and free of sagging.

Limit long sewer runs in exposed crawlspace areas or consider insulating sections to reduce freeze risks.

Avoid slow-dripping taps in winter unless necessary, as constant slow-flowing water can contribute to freezing in the sewer lines.

To prevent buildup and blockages, it's a good practice to auger out your main sewer line drain periodically, especially if you notice slow drainage or frequent backups.

Other Common Plumbing Leaks and Issues

While freeze-ups and improper installations are common concerns in mobile home plumbing, leaks and wear-and-tear can also cause significant issues. Regular inspections and maintenance can help prevent costly damage and ensure your plumbing system functions properly.

Hot Water Tank Failures

Hot water tanks have a limited lifespan, typically lasting 8–12 years depending on water quality and maintenance.

Over time, they can develop:

• Leaks at the base due to rust or sediment buildup.

• Pressure valve failures, leading to excess water discharge.

• Total failure or ruptures, which can cause significant water damage to the floor system if not caught in time.

To avoid unexpected failures, homeowners should:

Inspect the water heater annually for rust, leaks, or unusual noises.

Replace the unit proactively before a failure occurs.

Ensure the drain pan and pressure relief valve are functioning properly to minimize water damage risks.

Water Meter Connection leaks

Many mobile homes have a water meter connection near the entry point of the main water line. A common issue is the fitting loosening over time, leading to a slow leak. Often, this can be fixed with a simple tightening of the fitting using a wrench.

Frozen or Cracked Sewer Lines

During extreme cold, sewer pipes can freeze and crack, leading to:

• Slow leaks that drip into the crawlspace, damaging insulation.

• Major fractures, which can cause raw sewage leaks.

• Ice buildup inside the drain lines, restricting flow until warmer temperatures thaw the blockage.

Signs of a cracked sewer line include:

🚨 Unpleasant odors in the crawlspace or home.

🚨 Persistent moisture or dripping sounds under the floor.

🚨 Visible sewage pooling in the crawlspace.

Sewer Lines Strained from Home Shifting

•If a home settles or sinks unevenly, the sewer lines may bend, crack, or completely separate at the joints.

•This can result in sewer backups inside the home or leakage into the crawlspace.

•A professional should be consulted if shifting is suspected, as leveling the home may be necessary to correct drainage issues.

Soil Considerations Matter for Your Home's Foundation

Mobile home sewer systems are prone to leaks, blockages, and freeze-ups, often due to poor support, home shifting, or improper drainage slope.

These leaks can damage insulation, contaminate the crawlspace, and cause foul odors, requiring timely repairs to prevent bigger issues.

Beyond drainage concerns, another critical plumbing risk in mobile homes is the use of outdated Poly-B piping, which is known for leaking, deteriorating, and bursting over time. This is why many homeowners choose to upgrade to PEX piping, ensuring a longer-lasting and more reliable plumbing system.

Why Replace Poly-B Piping?

Poly-B to PEX Re-Piping: What You Need to Know

Polybutylene (Poly-B) piping was a common plumbing material used in mobile homes from the 1970s to the 1990s. However, over time, it has been found to be prone to leaks, deterioration, and bursting, leading many homeowners to upgrade to PEX piping, which is more durable and resistant to wear.

Common Issues with Poly-B Piping:

🚨 Breaks down over time due to chlorine exposure in municipal water.

🚨 Prone to pinhole leaks and bursting, especially at the fittings.

🚨 Higher risk of insurance issues—many insurance companies charge higher premiums or refuse coverage for homes with Poly-B.

🚨Prone to cracking in extreme cold, making it a liability in Norther climates.

Upgrading to PEX piping is a long-term solution that eliminates these risks, offering greater flexibility, freeze resistance, and longevity.

Challenges of Re-Piping a Mobile Home

Unlike traditional homes where plumbing is installed inside the walls, mobile home plumbing runs under the floor joists within the warm air gap. This means that re-piping requires cutting into the belly insulation and membrane, which can be costly and difficult to restore properly if done by someone unfamiliar with mobile home repairs.

Importance of Hiring a Mobile Home Plumbing Specialist

Since belly insulation repairs can sometimes exceed the plumbing job’s cost, it's important to hire a contractor familiar with mobile homes. A professional will:

✅ Minimize the damage to the belly membrane and insulation.

✅ Ensure proper sealing of the belly after the job is complete.

✅ Follow PEX installation best practices, preventing future leaks and freeze-ups.

When Should You Upgrade to PEX?

If your home still has Poly-B plumbing, you should consider replacing it:

If you’re already experiencing leaks or pressure issues.

If your insurance provider requires an upgrade.

If you plan to sell your home and want to increase its value.

A PEX upgrade not only ensures a more reliable plumbing system but also prevents future water damage and expensive repairs.

Professional Plumbing Services

Maintaining a reliable and efficient plumbing system in a mobile home requires proper installation, regular maintenance, and expert repairs. Whether you need a Poly-B to PEX re-pipe, sewer line inspection, leak repairs, or general plumbing maintenance, Get True has the expertise to keep your mobile home plumbing system in top shape.

Why Choose

Get True

Specialists in Mobile Home Plumbing – We understand the unique challenges of mobile home plumbing systems, from belly insulation repairs to sewer line slope corrections.

Preventative Maintenance & Repairs – Avoid costly damages by identifying small issues before they become major problems.

Expert Re-Piping Services – If your home still has Poly-B piping, we can professionally upgrade you to PEX for long-term reliability.

Freeze Protection & Insulated Skirting Solutions – We help ensure your plumbing is protected against Alberta’s harsh winters.

Is Your Plumbing Okay? Get a Free Estimate Today!

Don’t wait until leaks or freeze-ups cause expensive repairs! Contact Get True today for a plumbing inspection, repair, or upgrade consultation.

98 %

Satisfied

Customers

1,000+

Projects

Completed

10+

Experience